Woodworking Edge Banding Machine, All Intelligent Control System

1. Invention patent integrated double gluing unit: Two independent

quick glue pre-melting units +Two consolidated gluing systems.

2. Heavy-duty machine base + Consolidated pressure beam, greatly

increasing the stability of the equipment.

3. A complete intelligent control system, with 15 kinds of powerful

functions, real-time data transmission, real-time understanding of

equipment status.

4. The belt pressing beam makes the workpiece stable without

indentation, and the adhesion effect is more perfect.

5. Panel heating lamp + heating lamp after gluing

6. Six-roller pressing.

7. Four corner rounding motors

8. Two polishing units.

9. Equipped with cleaning agent device and wire breaking mechanism.

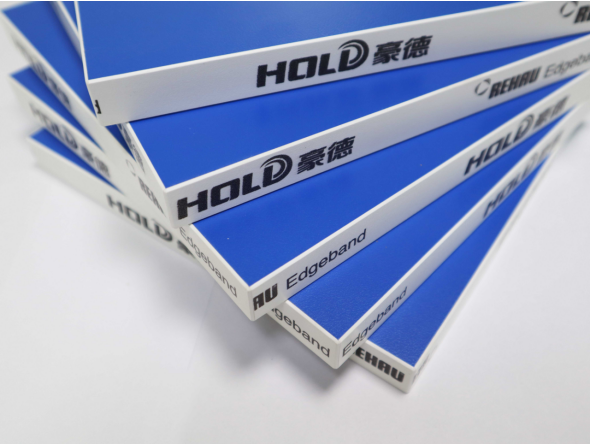

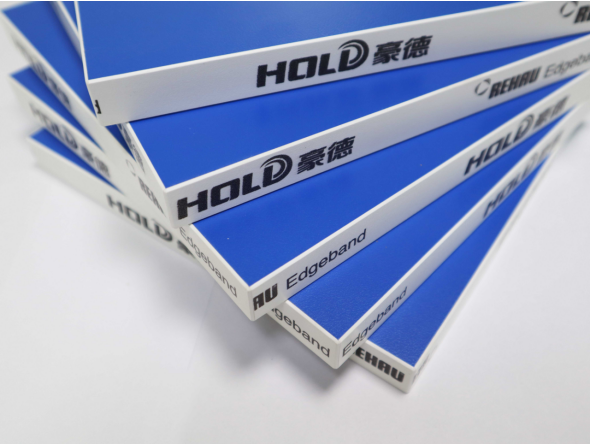

More detail of processing products

Technical specifications

| Project content | LASER S600 | Project content | LASER S600 |

| Electric lift | √ | Plate thickness | 10-60mm |

| Total power | 25kw | Plate length | ≥120mm |

| Dimensions | 9550x900x1750mm | Sheet width | ≥80mm |

| Feed rate | 14/20/23m/min | Working pressure | 0.6Mpa |

| Edge banding thickness | 0.4-3mm | Minimum sheet size | 120x80mm |

Main configuration

| name | brand | Brand image |

| Motor (pre-milling) | gsm |  |

| Motor (flush) | gsm |  |

| Motor (Rough repair) | gsm |  |

| Motor (finishing) | gsm |  |

| Motor (polishing) | gsm |  |

| Hardened reducer | Tuosheng / Zhouyi |  |

| Cylinder block | Taiwan Yadeke / 100 million days |  |

| Guide rail, slide | HTPM |  |

| Solenoid valve | Taiwan Yadeke / AirTAC |  |

| Frequency converter | INOVANCE |  |

| an electric appliance | Korea LS |  |

| Programmable logic controller (PLC) | INOVANCE |  |

Configuration description

Consolidated beam

It greatly increases the rigidity and strength of the pressure beam

and ensures the stability of the pressure beam in high-strength

operation.

New Machine Base

Super heavy-duty, integrated rail seat, annealed and machined. The

guide rail is installed on the whole coherent integrated guide rail

seat, and there is no suspension in the middle, so the stability is

particularly high.

All intelligent control system

Bar code scanning function,

Intelligent heating and heat preservation

Stepless speed change

Data statistics

Production report

15 kinds of powerful functions, real-time data transmission,

real-time understanding of equipment status, one key production

report.

Belt pressing Beam

The workpiece is stable without indentation.

Separator unit

It has the function of separation and solves the problem of hot

melt glue polluting the board surface after gluing.

Pre-milling

After milling by milling mechanism, all kinds of defects on the

machined surface can be removed, such as ripple marks, burr edge or

non-vertical phenomenon, so that the edge banding strip and plate

fit more closely, and the integrity and beauty are better, so as to

achieve better edge banding effect.

Electric pressure beam lifting

Reduce the labor intensity, increase efficiency and accuracy.

Plate heating unit + heating after gluing

When the temperature is low, heat the surface to be glued before

gluing to make gluing more firm and edge sealing more perfect.

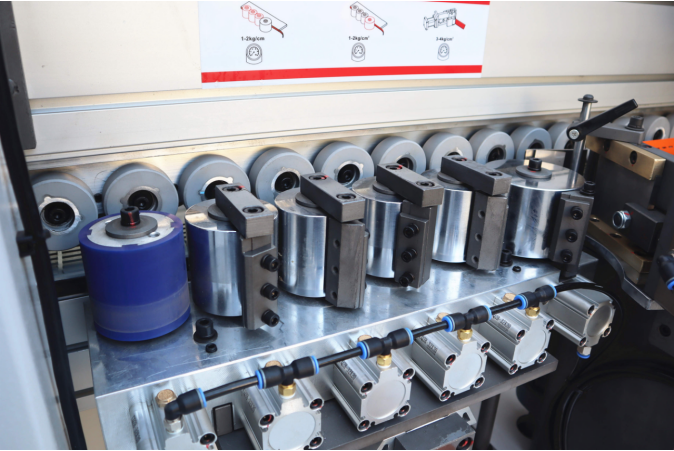

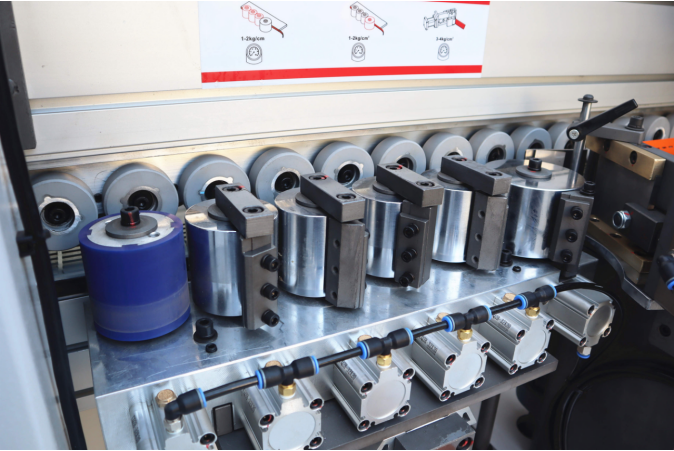

Two independent quick glue pre-melting units +Twins gluing systems.

Invention patent, quick assembling and disassembling, quick

positioning; Each glue pot can be used alone or at the same time;

EVA or PUR can be used.

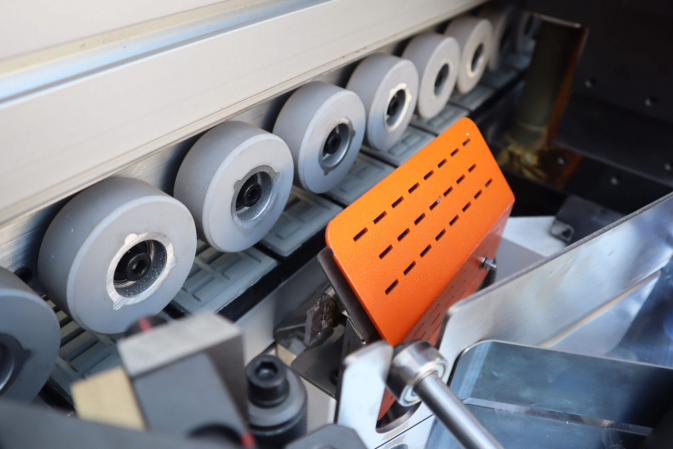

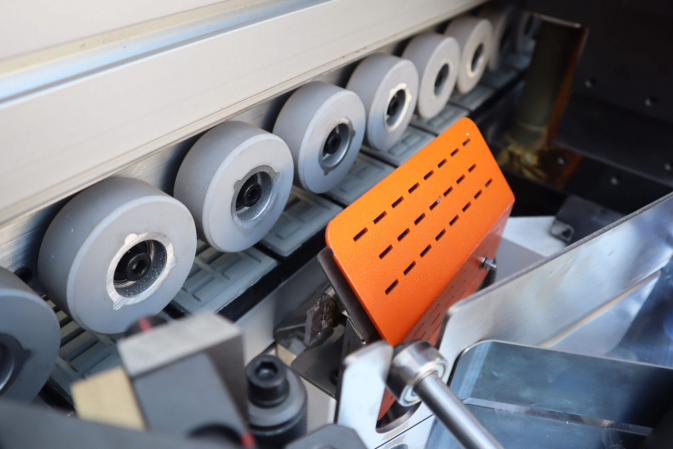

Six pressing rollers with glue scraping blades.

Strong pressing force, edge banding is more suitable, scraping off

the excess hot melt glue, making the glue line smaller and the edge

banding effect more perfect.

Double guide rail alignment

Cut off the front and back edge banding quickly, and match the

front and back of the two saw blades to achieve high precision and

high efficiency.

Trimmer

Cut off the extra edges on the sides of the edge banding quickly

and neatly to make the edge banding effect more perfect.

Fine Trimmer

The edge banding is protruded from the top and bottom board, and

the redundant edge banding is trimmed into an R-angle shape so that

the edges of the edge banding are flush and smooth with the upper

and lower surfaces of the board.

Four head corner rounding unit.

The tracking and profiling system with four motors and directional

cutting makes the action more accurate and stable; The edge fillet

(chamfer) of the plate is processed to make the four corners of the

plate smooth and beautiful.

Scraping

Remove the grain mark left by the trimming unit.

Edge's chips remove device + Glue scraper + cleaning device

Edge's chips remove device: to solve the problem that the scraping

edge ribbon affects the normal operation of the flat scraper, or

directly winding the polishing unit causes the motor to be stuck

and burned.

Clue scraper: remove the excess hot melt adhesive on the surface of

the workpiece.

Cleaning device: diluting residual hot melt adhesive, easier to

clean.

Twins polishing

Throw away the excess glue mark to make the edge banding smoother

and cleaner.

Hard tooth surface gear motor

5 kW power, stable operation.

Unique design: rubber coated roller

The front and back of the auxiliary joist are equipped with

rubber-coated supporting wheels to prevent the plate from being

damaged during feeding and discharging.

If want to know more about our products by video, please click the

below link:

About our company

One-stop solution for interior furniture equipment and wooden door

equipment

HOLD Machinery was founded in 2004, focusing on the development of

a full range of furniture machinery equipment and wooden door

machinery and equipment, providing furniture and wooden door

enterprises with solutions for whole factory planning and

automatical production lines, providing customers with excellent

quality, efficient and stable products, and high-quality service.

HOLD Machinery has served the majority of furniture and wooden door

enterprises in more than 40 countries and regions around the world

and has won wide admiration from customers.

FAQ:

1. Do you have the machine in stock?

Sorry, we don't have the machine in stock, edge banding machine has

many options such as voltage, speed, function, and so on, So it's

hard to prepared samples.

2. How long is your delivery time?

For our standard model, the delivery time is around 1.5~2 months.

For the customized model, the delivery time is around 2~3 months.

It depends on the client's project and quantity.

3. Do you have a factory?

Yes, we have our own factory and we promise direct sales at a

competitive price. Welcome to visit our factory at any time.